Excellence in service"

and fame,

clients’ trust,

and a proven record of production volume in the latest year are proof of Tnlx’s success and also proof that TNLX will not stop improving and moving forward in order to maintain the status as the biggest

Production capability : highest production volume in a year. TNLX is ready to support any manufacturing demand, with the power of 840 experienced weavers spreading across 5 standardized factories including the headquarters in Bangkok and other bases in Lamphun, Kabin Buri, Prachinburi and Mae Sot, Tak

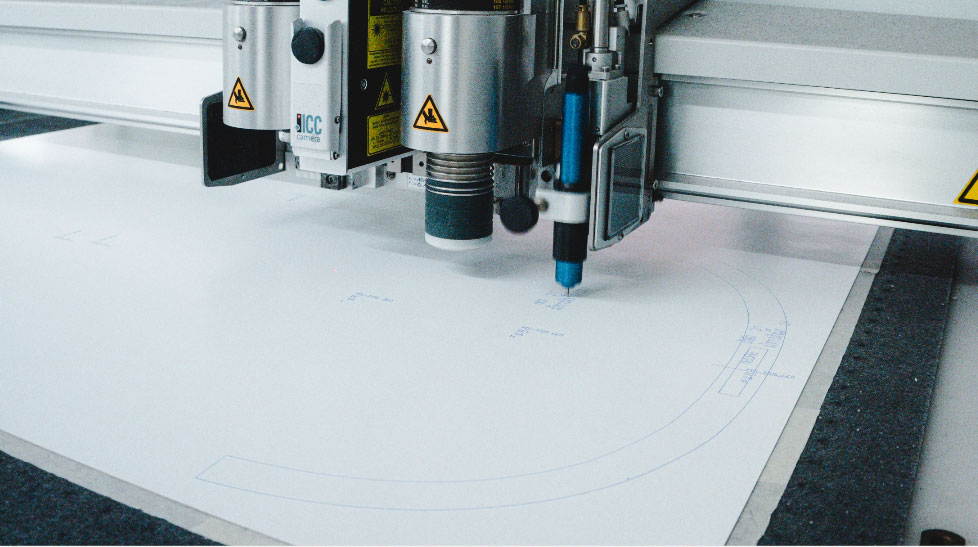

ExperienceKnow-hows regarding all processes of production that have been gained and collected during years of hands-on experiences are the true strength of TNLX. We have our own way to collect such detailed, necessary information as special sewing techniques and unique styles of creating pattern mock-ups according to clients’ specifications. The collected know-hows are not only the unique identity of the company, but also the rich source of knowledge that can be transferred to a new generation of “TNLX.”

We give opportunities for our crew to develop and sharpen their skills at factories in Japan since we know that Japanese industrial standards and quality are globally acknowledged. We collect knowledge from workshops and trainings in Japan to create the Sensei system that have continued producing specialists for 4 generations. We have 23 specialists from the Sensei system to systematically transfer knowledge to weavers and technicians for the sake of the company and the best result for our clients.

Weaving machine is an important tool and also the true core of quality. The company therefore invests so much in improving modern weaving technology.

The company has a full system of quality check for all processes of production from ideas to products. The quality examination is enhanced by the use of modern technology and reasonably-set standards.

The company values all staff members and believe that they are the true power of production. Hence the company holds tons of workshops and tests to keep practicing and developing staff members of all sectors including business team, designer team, weaver team, and quality check team to ensure united collaboration under the standards of the company.